Products & Solutions

BULLBLEND

Achieve gentle and uniform flow within the vessel with low power consumption!

BULLBLEND, a high-performance and compact impeller mixer, combines the excellent mixing capabilities of MAXBLEND with the space-saving design of small impellers to achieve gentle, uniform flow within a vessel using low power.

Structure

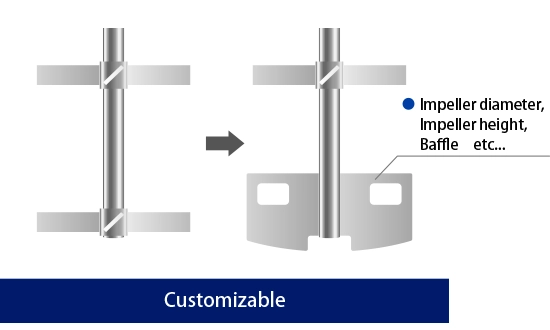

Like the MAXBLEND impeller, BULLBLEND can be customized to meet specific process requirements—such as impeller diameter, height, and baffle shape. Unlike larger impellers, it can also be combined with other small impellers. This makes it possible to upgrade performance in existing installations by reusing the current drive unit and replacing only the impellers, resulting in reduced investment costs.

Bullblend features

Like the MAXBLEND impeller, BULLBLEND can be customized to meet specific process requirements—such as impeller diameter, height, and baffle shape. Unlike larger impellers, it can also be combined with other small impellers. This makes it possible to upgrade performance in existing installations by reusing the current drive unit and replacing only the impellers, resulting in reduced investment costs.

-

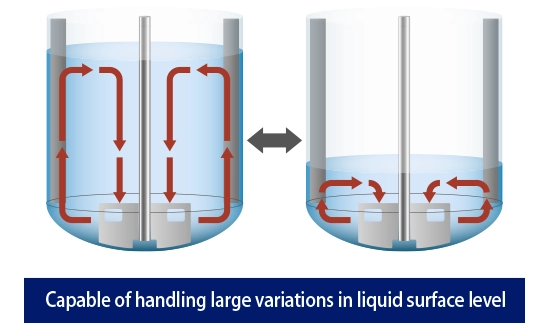

Capable of handling large variations in liquid surface level

-

Excellent particle dispersion and mixing performance

-

Low shear suppresses fine particle generation

-

Compact design enables easy cleaning and reduces material buildup

-

Suitable for viscosity ranges from 1 to several thousand mPa·s (turbulent flow region

-

Optimization at low cost by utilizing existing drive units

Applications

-

Crystallization

-

Slurry discharge

-

Acid precipitation, etc.

Excellent Mixing Performance

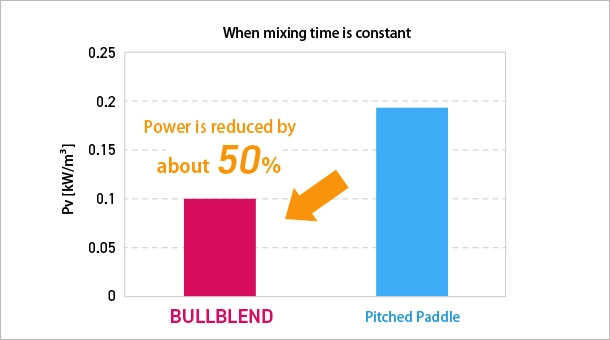

BULLBLEND can reduce power consumption by approximately 50% while maintaining the same mixing time as conventional systems, contributing to lower CO₂ emissions.

As a result, it is widely adopted in various processes such as crystallization, slurry discharge, and acid precipitation.

【Mixing Conditions】

Tank Diameter: 310mm, Viscosity: 100cP, Liquid Volume: 21.6L, Baffles: 4 Flat Plates

Mixing Performance Comparison at Constant Mixing Time

High Solid Dispersion Performance

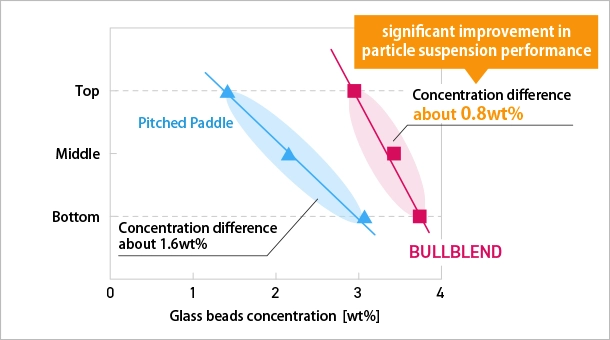

When compared under the same power conditions, BULLBLEND significantly improves solid dispersion performance, enabling solid particles to be suspended even near the upper interface. As a result, vertical concentration differences are minimized, leading to a more uniform mixing state.

This is especially beneficial in processes involving solid-liquid mass transfer, where the transfer rate is enhanced, allowing operations such as dissolution to be completed in a shorter time.

【Mixing Conditions】

Tank Diameter: 310mm, Viscosity: Approx. 1cP, Liquid Volume: 23.8L, Baffles: 4 Flat Plates, Particles: Glass (Diameter 350-500 μm)

Comparison of Solid Dispersion Performance under Equal Power Conditions

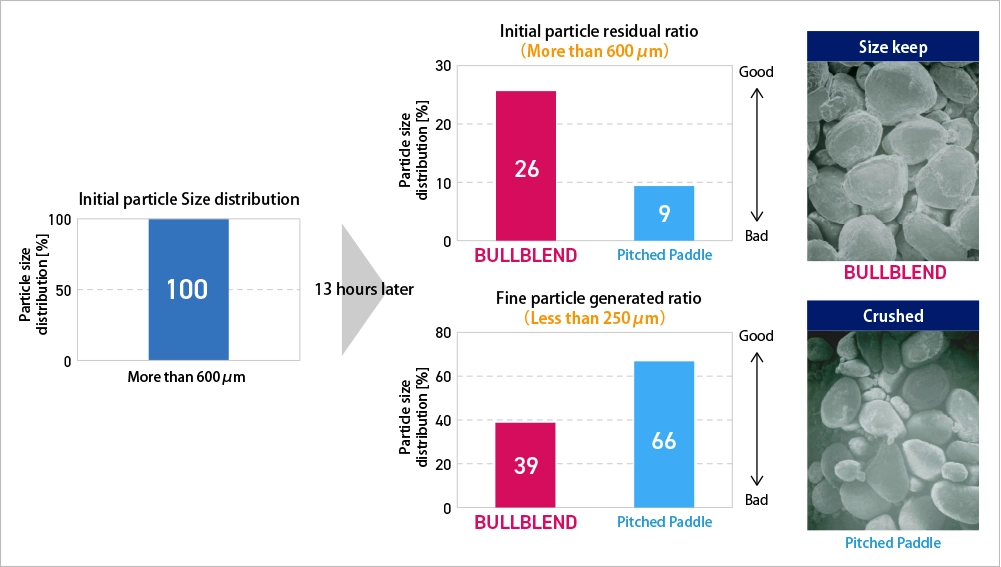

Low Shear Performance

The graph shows the results of a crystal fracture test using boric acid.

After 13 hours of mixing at the same power, BULLBLEND generated fewer fine particles than the inclined paddle impeller, confirming its capability for lower-shear mixing compared to small impellers.

Low-shear mixing suppresses the generation of fine particles and helps maintain the quality of precipitated particles, making it ideal for processes such as crystallization where particle breakage must be avoided.

【Mixing Conditions】

Tank Diameter: 310mm, Viscosity: Approx. 1cP, Liquid Volume: 26L, Particles: Boric Acid